LVT vinyl floors: everything you need to know

Before we start talking about vinyl floors it is necessary to debunk the myths in which consumers often still believe. PVC floors are not to be confused with laminate floors or linoleum. Linoleum is in fact a natural-based product consisting of a mixture of wood flour, pigmented resins and linseed oil, while laminate floors are composed of a base of wood fiber (HDF or MDF) to which several layers are applied such as the decor printed on special paper, a transparent protective layer to preserve them over time and a lower counterbalance layer to avoid deformations. The recent success of LVT (luxury vinyl tiles) PVC flooring is mainly due to the fact that these new products have eliminated practically all the disadvantages associated with these types of materials, such as poor resistance to high temperatures, high foot traffic noise, which can be really annoying, especially in working environments, or the compromise of the slabs in case of water infiltration through the joints.

Composition of PVC floors

LVT vinyl floors generally have a PVC (polyvinyl chloride, also known as polyvinyl chloride) core and are composed of four overlapping layers. The transparent surface layer is perhaps the most important layer, since depending on its thickness there will be different degrees of abrasion resistance of the floor, which is due to the circulation of people, objects and animals. These thicknesses range from 0.20 mm to 0.70 mm, where 0.20 slabs are destined for a purely residential use, with a guaranteed durability over time for a smaller number of years, while 0.70 slabs represent the minimum thickness for industrial use. In addition to the thickness, to evaluate the quality of the purchased product, attention must also be paid to the embossing and relief of the textures, which, are often a sign of high-quality products. The layer underlying the protective one, is the decorative film on which the graphics of the material are printed. Also in this case, the quality products differ because of the high number of different graphics and the detail with which wood and natural stones are reproduced. The heart of the vinyl sheets is represented by the third layer where the vinyl chloride polymer acts as a binder for the glass fibers that compose it. This layer is normally less thick in floors with adhesive installation and greater in floors with a click-system, considering that this layer determines the structural stability of the slab, the sound absorption and the softness of the surface, it is easy to understand how click installation generally guarantees a superior performance. In the case of adhesive installation, there is also a last layer that performs various functions such as that of making the air circulate better between the substrate and the product in order to reduce the formation of humidity and that of better clinging to the substrate through a specially designed surface.

The different types of vinyl flooring

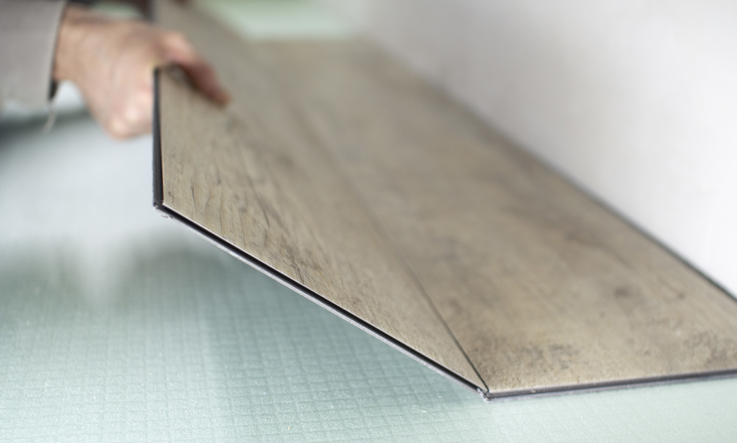

PVC floors differ substantially in the type of installation for which they are created. The slabs that are designed for an adhesive installation normally have low thicknesses and have an adhesive film which is already pre-installed on the back of the tile. They are simple to install and some manufacturers use special glues that allow the PVC sheets to be installed and removed several times. The plates that are designed for click installation have a greater thickness to allow the jointure between two slabs, but they are extremely simple to install and lend themselves more than any other to DIY installations, with the advantage that in case of replacement it is only necessary to lift them to restore the previous floor. The slats or rolls that must be glued with more traditional methods, are those with a lower thickness, but once installed they can no longer be lifted if not with a complex mechanical detachment. On the other hand, they are the most stable vinyl floors ever.

What are the advantages of vinyl floors?

As we have seen previously, there are some advantages which are directly related to the type of production. The best LVTs are distinguished by the quality of the design and the relief of the textured surface, but the main advantage is given by the ease of installation and the low thickness. The ease and speed of installation is particularly evident for all click installation products, as it is only necessary to put the slats or plates together, slide them into the joints and then seal the joint with a rubber hammer, in order to have a product of great beauty. Moreover, the softness of PVC makes it extremely easy to cut: a simple cutter is enough to make all those cuts that would otherwise entail expenses for equipment and difficulties in execution. A considerable aspect to be aware of when purchasing interlocking PVC floors, is the possibility of replacing even a single slab, without having to lift the entire floor in case of damage or need for maintenance. Only a few manufacturers can create this kind of replaceable slabs. The low thickness slabs, which vary from 2 to 6 mm depending on the type, can be installed directly on existing floors, avoiding expensive and noisy demolition works. Compared to wood, it is light resistant, not showing any chromatic variations over the years even in areas that are exposed to direct sunlight. Last but not least, the eco-sustainability of this material which allows it to be 100% recycled once it is removed and which does not contain lead, formaldehyde or solvents.

What are the disadvantages?

First of all, it must be said that we are talking about a product that has not yet matured a sufficient number of years in the market to make any valid considerations to this matter. However, the difference between the first vinyl floors and the current ones is enormous, which is a sign of a positive trend that is still going on. As regards sustainability, it should be borne in mind that about 90% of PVC floors are made in China. This is since their production is considerably polluting and to maintain competitive prices, we obtain supplies from countries where anti- pollution laws are not as rigid as in Europe. But here you can find only LVT products that are made in Europe according to all EU regulations on the protection and safeguard of the environment.

The nature of the vinyl which tends to adapt to the substrate on which it is installed, requires that if it is installed on existing floors, the previous joints should not be wider than 4 mm, vice versa, it is necessary to do a preliminary leveling before proceeding with the installation, otherwise the lattice of the underlying joints could become visible as time goes on. In the event of significant water leaks, such as pipe breakage, leaking dishwasher or washing machine, it will be necessary to dismantle and then reinstall the entire floor, in order to completely eliminate the water that has penetrated between the joints. Not doing so would cause the formation of mold and bad smells, with consequent health hazards and foul-smelling environments. From this we understand how this type of LVT plates is not suitable for environments with rising humidity. Compared to porcelain stoneware, we must also include the reduced scratch resistance in the shortcomings of PVC floors. Even if they are high-quality products, PVC floors may will never reach the technical characteristics of porcelain stoneware.

Conclusions

To this date, porcelain stoneware remains the material with the best technical characteristics on the cladding market, and if you are thinking about purchasing a new house or you have a substantial budget for your renovation, our advice is to take this into consideration. Except all the disadvantages listed above, in cases of renovation of shop floors, offices, commercial activities or houses for rent, vinyl floors are the best alternative to stoneware, because it is possible to install the new floor just in a few hours by yourself. In fact, they stand out for their versatile offer, ease of installation, aesthetic quality, eco-sustainability and installation speed, in particular in the click system products.